NI Integral Solutions

for Teleflex cables

NI Integral Solutions is a worldwide unique package specially developed to optimise the cleaning and lubrication processes of Teleflex cables and to reduce the radiation exposure of the staff in charge, thanks to its remote operation.

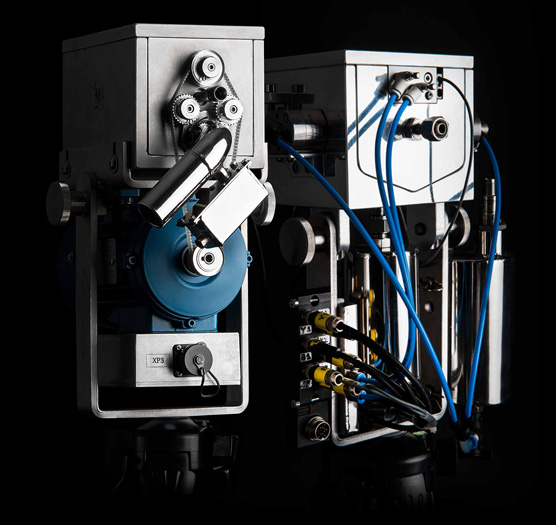

NI Teleflex Brushing

Teleflex cable cleaning

for L and U plants

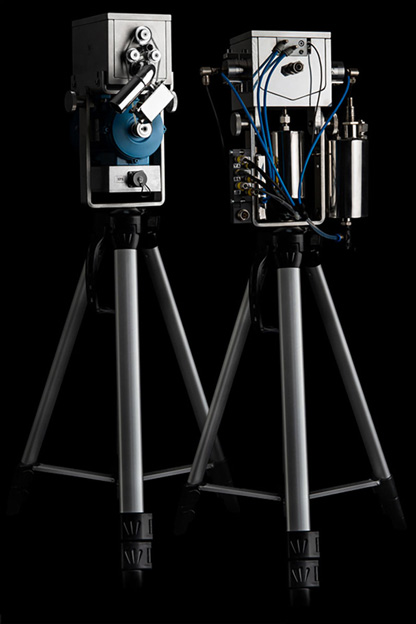

NI Teleflex Lubricator

Teleflex cable lubrication

for L and U plants

A

much

simpler and safer system

The NI Integral solutions package is characterised by its simple and safe operation. Both machines are connected to the reference channel just once during installation, once to the valve at one end and once to its outlet at the other end. This enables cleaning and lubrication of the five cables without the need for repeated handling of the probes.

Once installation is complete, the whole process can be carried out with a maximum of 2 operators: one in the control room, in charge of controlling the drive unit, and one outside the Incore room, managing the cleaning and lubrication of the cables through their respective control boxes.

NI Teleflex Brushing is a New Incore patented machine intended to replace the current Teleflex cable cleaning process. Its technology allows this work to be carried out faster, safer and more efficiently.

Automatic

NI technology enables automated cleaning with less exposure for staff in charge.

Simple

Its intuitive control box only has two buttons, making it very easy to use.

Smart

It has a suction outlet for dirt removal controlled by a pressure vacuum gauge which, in case of interruption of suction, stops the machine operation, which will be reported to the operator by an indicator light on the control box.

Full lubrication

Its design and the possibility of remote control allow 100% lubrication of the Teleflex cable, unlike the traditional method where, due to radiation exposure, it is not possible to reach the most critical area of the cable.

Uniform and efficient

Pulsajet injection guns provide homogeneous lubrication; and the recovery tank allows for the recovery of excess neolube.

Reduced staff

Furthermore, in plants with an Ethernet connection in the control room, the entire process can be carried out by a single operator, thus reducing the number of staff required.

Safer

than ever.

The two machines that make up the pack have been designed so that both installation and operation can be carried out quickly and easily by a single operator. Both are operated via intuitive, wireless controls, so that the operator can operate them remotely without the risk of contamination or radiation.

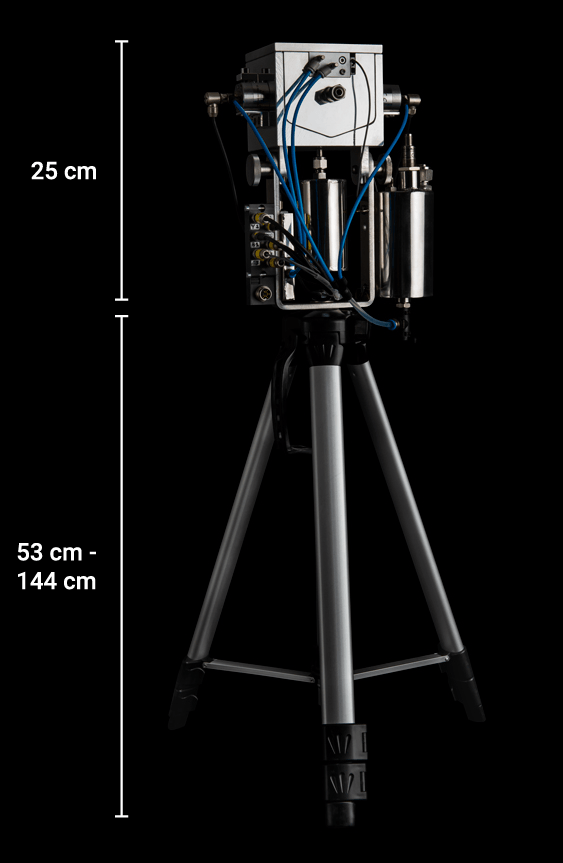

Small and portable

Their design makes them quick and easy to install, dismantle, clean and decontaminate, which can be carried out by a single technician. In addition, the height of each machine can be adjusted using the foot provided, which allows for flexible handling.

Contact

Or simply let us know what you need, here >

+34 645 143 245

info@newincore.com

43892 – Miami Platja, Tarragona (España)